Firearms Restoration, Repair, Cleaning, Conservation and Manufacture

WE CLEAN AND REPAIR RUSTY GUNS!

projects

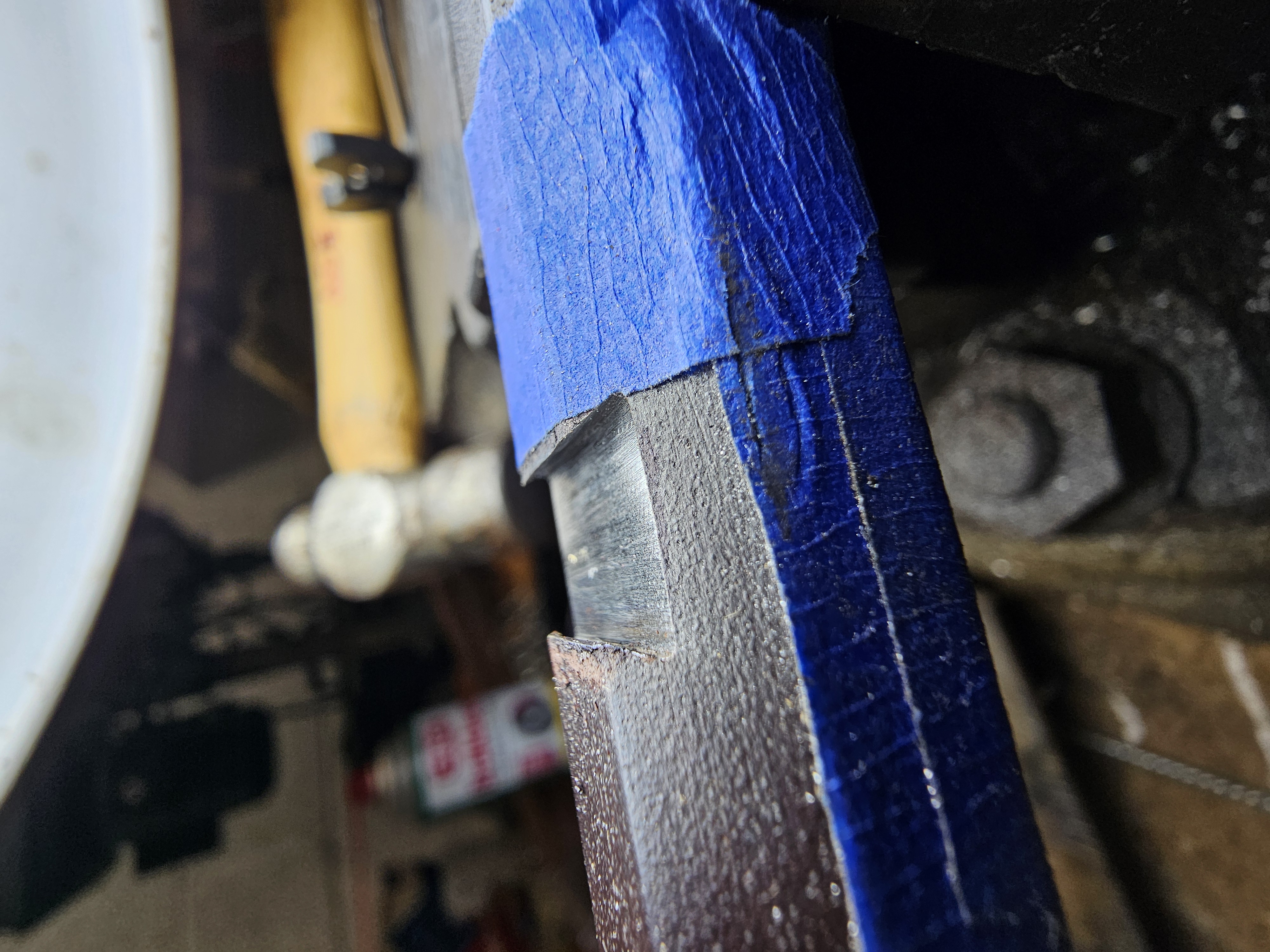

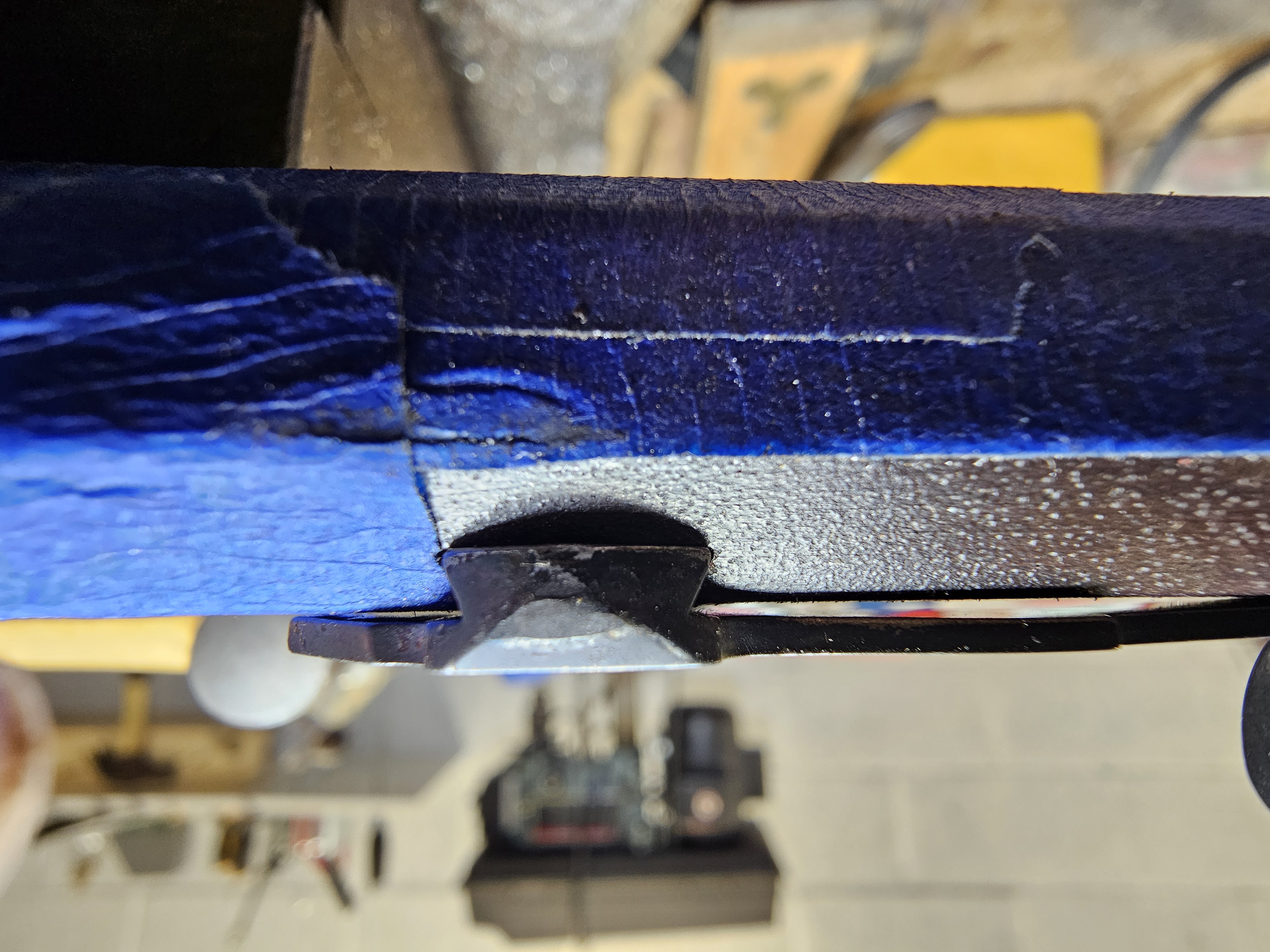

LAR Grizzly 50

Problem: factory extractor not heat treated properly-subject to breakage causing weapon to become a paperweight. Replacements not available.

Solution: Handmade replacement parts, has stood up to 1000's of rounds. Only place in the world to obtain LAR Grizzly extractors are from 2nd Amendment Arts.

|

|

|

|

Anzio Ironworks 50 BMG

Problem: factory ejector pin bent.

Solution: Handmade replacement ejector pin

|

|

Aftermarket Dovetail Sight Install

Perfect fit!

The first 1/4 can be pressed in by hand, and the other 3/4 must be drifted in with a small hammer and bronze punch.

|

|

|

|

Old rifle stock with screw holes.

I first repaired the crack with 2mm threaded brass wire and epoxy and reset it below the surface of the stock.

Once the epoxy had dried, I used a small diamond-shaped plug of walnut to cover the screw hole.

In a short while, it will darken to blend into the stock finish and be hard to distinguish.

|

|

|

|

|

|

People ask, "Where do I find a thin threaded brass rod?"

I make it.

Brazing rod is chucked into a drill and run through an M3x0.5mm die nut.

Easy peasy.